- info@techzology.com

- Saudi Arabia, Bahrain, US, UK, EU

IMS Solution management system can help to improve the quality of processes and products, control environmental. IMS Solution enables businesses to operate within the standards, policy, strategy, and legal framework to create a safe working environment.

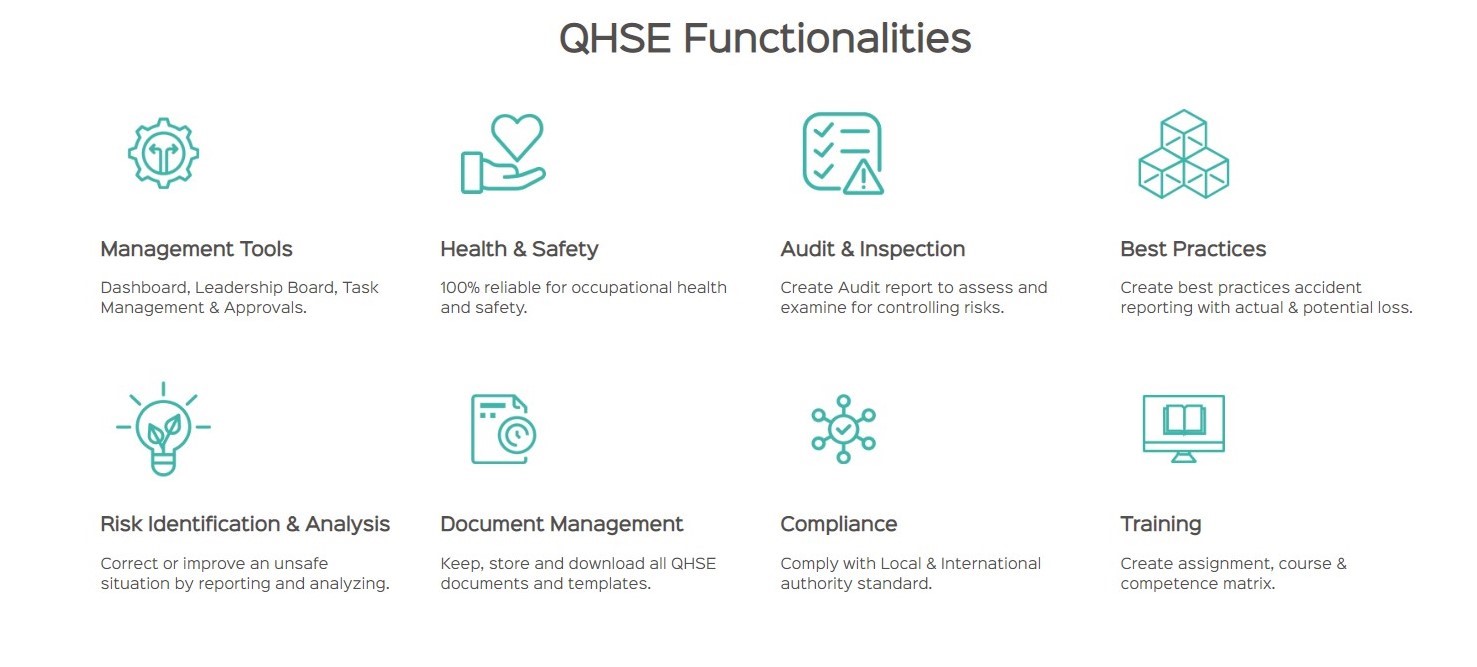

QHSE (Quality, Health, Safety and Environment software) is a tool that provides organizations with a system that connects all your safety management goals to a unified system. QHSE tools are extensively used in various sector that includes oil and gas, Petrochemical, Power Plants, Transportation, manufacturing, construction, mining, pharma and utilities.

Our IMS Solution is a modern and comprehensive cloud-based software platform that can be deployed with optimum efficiency for QHSE Management. All the requirements of HSE can be configured to suit company requirements.

To know more how Techzology help achieve your business objective, contact us:

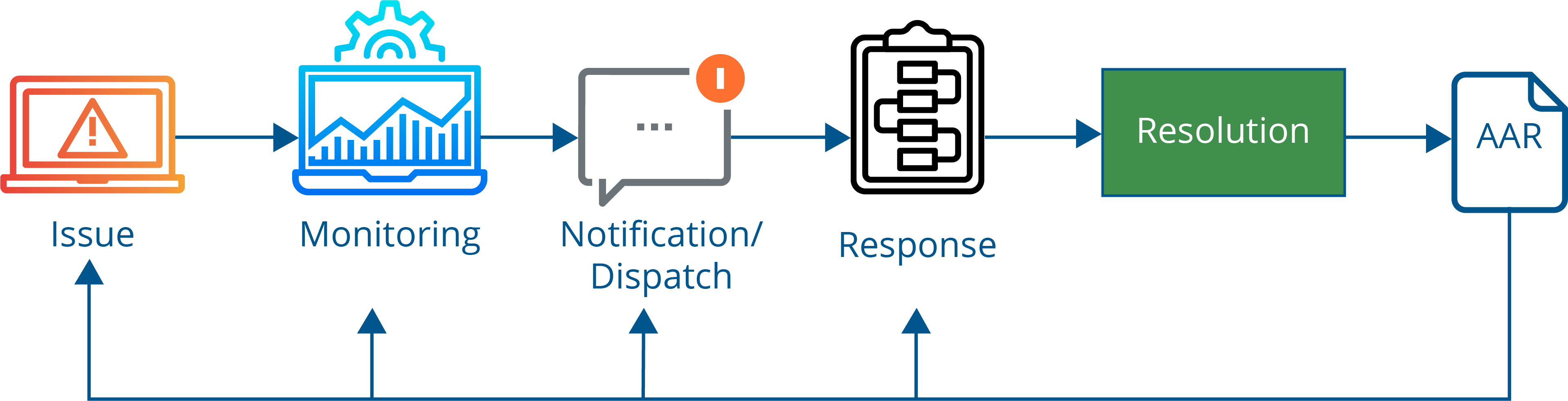

An Incident Reporting and Management system helps an organisation in reporting, investigating, and analysis of all incidents, accidents, and significant near misses. The benefits of IMS system include:

To know more how Techzology help achieve your business objective, contact us:

To know more how Techzology help achieve your business objective, contact us:

To know more how Techzology help achieve your business objective, contact us:

To know more how Techzology help achieve your business objective, contact us:

To know more how Techzology help achieve your business objective, contact us:

Studies have shown that a major contributor to industry incidents and major risk events is human behaviour. Small incidents, near-incidents or process excursions are leading indicators of increased operational risk levels and are critical in the quantification of the risk impact. We provide the platform to record, track and respond to such incidents and make a major contribution to reducing operational risk relating both to human safety and environmental impact.

Critical ooperations in the oil and gas, petrochemical, fertilizer, and chemical industries are high risk, with potential hazard to personnel, property, and environment. A structured approach is required to ensure procedures and processes are followed and standards are implemented along with monitoring & inspection of critical equipment. The ability to prioritize and address high-risk items can prevent risks of fire, explosions, and shutdowns all whilst saving the asset owners time and cost.

Traditional inspection methodologies work on a fixed-period basis without considering the risk, while in contrast RBI, the risk is viewed as the product of the consequence and probability of a failure event. This ensures the equipment with high risks are prioritized and focused for inspection activities to reduce the risk level.

To know more how Techzology help achieve your business objective, contact us: